- Case study

Syncing supply and demand for an electronics giant

How augmented intelligence helps predict and adjust to fluctuations in demand and improves the inventory availability

Who we worked with

Panasonic Corporation, a Japanese multinational electronics corporation and one of the largest electronic products manufacturers in the world.

How we helped

We deployed full stack analytics built on Genpact Cora, our AI-powered digital business platform. This included a supply chain data lake, decision support engine, and data visualization tool that feeds into planning and decision processes and a new agile operating model.

What the company needed

Visibility of the data in its complex supply chain to better forecast supply and demand, free up working capital, and banish manual processes and slow decision cycles.

What the company got

Visibility of end-to-end supply chain data that provides a consistent, reliable bedrock for advanced analytics and incorporates more sophisticated demand signals.

Overall forecast accuracy has improved by up to 75%, leading to 30% less working capital tied up in inventory. Slicker processes have boosted sales team productivity by 33% and cut the supply chain decision cycle from monthly to daily.

Challenge

Boost competitiveness by releasing working capital tied up in the supply chain

With its 12 third-party factories, 13 product categories, more than hundreds of channel partners, and thousands of SKUs, Panasonic is one of the largest electronic product manufacturers in the world, and its supply chain is one of the most complex. With vital data hidden across different stakeholders that muffled demand signals, the company's supply chain forecasting and planning processes couldn't accurately match demand to supply.

Low forecast accuracy led to blocked working capital, rising stock, and operational inefficiencies. The production-to-delivery cycle took up to three months and couldn't react to changes in demand – leading to overstocking and product shortages.

Legacy processes and multiple databases were a challenge. The sales, operations and planning processes either couldn't access the right data or relied on inconsistent data and involved too many manual processes.

Panasonic knew that it had to reboot its supply chain to take advantage of online sales, fend off global competitors, and meet customers' expectations.

Solution

Bring down silos. Foster new ways of working. Embed insights into everything the company does

We started by carrying out granular analysis of the end-to-end sales and operations planning processes to find critical gaps and issues. Frequent surges in demand and ad hoc forecasts from channel partners added to forecast complexity. On the supply side, we found defective components and delayed shipments that frustrated customers.

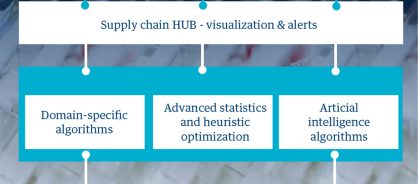

We implemented full stack analytics and decision process transformation (Figure 1) built on five layers to model complex relationships and increase forecast, supply network planning, and inventory planning and allocation accuracy. For this we migrated on-premise data to a fast and reliable Amazon Web Services (AWS) platform to store and manage the solution.

Genpact hosted and managed the solution, guiding the cloud-native build process end to end, from architecture design to deployment. After launch, we delivered robust application support through proactive monitoring, regular updates, and performance optimization to minimize downtime. Our solution also encompassed security management, disaster recovery, and compliance with industry standards, providing Panasonic with a reliable, scalable environment tailored to their needs.

Figure 1: Full stack analytics and decision process transformation

The first step was to create a supply chain data lake, enabled by Genpact Cora, our AI-based digital business platform hosted on AWS. This data warehouse encompasses 32 different data sources on which to base demand forecasts. A decision support engine applies domain algorithms, artificial neural networks to detect demand, and text mining on promotion records to the data lake to identify regularities, relationships, and patterns between demand variables, including the impact of special events such as promotions.

The supply chain HUB then provides data visualization and alerts. Hierarchy and role-driven dashboards provide easy data drill-down for review and monitoring, and integrated insights provide each stakeholder with a real-time view across the supply chain. We helped Panasonic redefine its decision-making metrics and KPIs to ensure that supply chain decisions support overall company goals.

Finally, we designed a new agile operating model that supports agility rather than efficiency (Figure 2). A managed services desk for analytics, data management, and infrastructure now provides sophisticated analysis of the improved data and a quicker response to market fluctuations. The inventory forecasting model now operates on an intelligent planning platform that uses sell-through data – a more accurate measure of end-customer demand than sell-in data. This means more accurate demand modeling and improved trade promotions such as discounting and bundling.

We worked closely with the Panasonic team throughout. Regular meetings with stakeholders, including sales teams and product managers, were held during the transition period to discuss progress and the processes being developed.

Figure 2: Agile operating model

Impact

A nimble, alert supply chain that works behind the scenes to delight customers

This supply chain pivot shifted the management team's focus from data management and analysis to making supply chain decisions that support growth. The supply chain is more agile and more closely aligns inventory, production, and logistics with market demand. Fulfillment time is faster, which means shorter wait times and delighted customers – key advantages in such a competitive environment.

Full stack analytics and the end-to-end view of the supply chain has enabled:

- Up to 33% more accurate forecasts

- 30% less working capital tied up in inventory

- Supply chain decision cycle cut from monthly to daily

- 51% more productivity for the business teams

Supply and demand are now working in sync – and that's just the beginning of the competitive advantage Panasonic expects to reap in the future. Customized user interfaces for warehouses and factories, analytics to decide the most cost-effective way to ship goods, and supplier/carrier data that integrates with purchase orders are all on the agenda.